Etsy has this series called Quit Your Day Job where they interview sellers who left the 9-5 world to craft full time. And yesterday they had a live Virtual Labs chat with one of the quitters.

As someone who has left the stable comfort of a regular paycheck I’m really interested in talking with other people who’ve taken the plunge about the challenges, surprises, etc. Unfortunately the Storque articles are kind of cut-and dry… I think geared towards newer sellers, so they don’t really give me what I’m looking for.

In light of that, here’s my interview. With myself. Because I’m narcissistic like that. Half of these are questions I find interesting, the other half are things everyone seems to ask.

What made you decide to go full-time with the crafting?

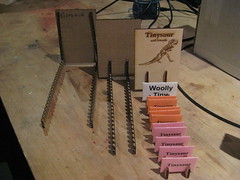

It was an accident. I quit my day job in November with the intent of finding another after the holidays and was selling Tinysaurs and other crafts to keep myself occupied. They got picked up by BoingBoing and suddenly I was so busy I had to recruit friends to help me pack and ship orders.

This is actually my second attempt to make a living doing craft shows and wholesale. When I got out of college I was selling jewelry at craft shows. My degree is in metalsmithing. For a number of reasons I wasn’t doing that well. When I got an opportunity to take a full-time job in New York I jumped at it, leaving my jewelry business behind. Which is why it’s a little surprising I’m back at it again; I swore up and down I was done with craft shows when I moved up here.

How do you keep up with demand?

Theoretically by being organized and working efficiently. Lets just say that organization is something I’m working on. Right now demand is at a point where I can get away with being a little scatterbrained, but I really need to sit down and work out a system for all this stuff. I do a lot of running back and forth, which is a time waster.

Are you worried about becoming too successful?

I wouldn’t go so far as to say I’m worried. It’s something I keep an eye on, but I think I’m prepared to scale up if things hit the big time. I spent one day where I did nothing but make Tinysaurs, start to finish. I wanted to see how many I could crank out in a day. I use that as my baseline for when I’ll need to hire a part-time assistant to do some of the more menial stuff like folding instructions.

Do you think you’d have to raise your prices if you hired an assistant?

No, when I first set up my prices I made a spreadsheet with the cost of each product broken out. I estimated how much time I spend making each one and built a reasonable hourly rate ($15/hour for NYC) into the price of each Tinysaur. So if I ever have to hire anyone their cost is already built into the price, and in the meantime I’m getting to keep that hourly rate. So right now it’s sort of like I’m being double-paid. It’s nice.

How do you market and promote yourself?

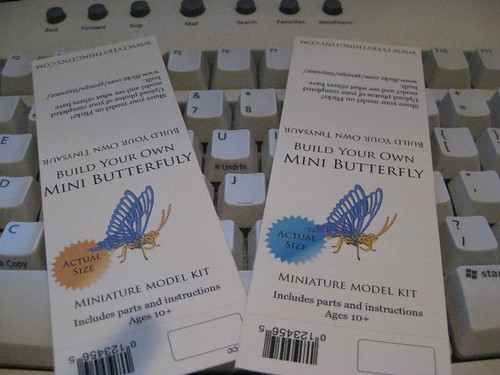

So far it’s all been word-of-mouth and a few careful targets. I send links to blogs periodically and look for places where it would fit in. I mailed a few samples to some smaller magazines. For craft shows I have some samples I give out as promos. Not just business cards, but actual tiny samples of a dinosaur skull. Some products lend themselves better to sampling than others, but I think if you can come up with a good one it’s vastly more valuable than just a business card with your URL.

So if you’re not buying ads all over the place, what’s the secret to your success?

Having a unique and interesting product. Tinysaur himself does 90% of the work for me. If you’re having trouble getting a good groove going with your business, take a step back and look at your product. Do an Etsy search for it… how many of the results are almost identical to what you make? What would make your product stand out from those? Sometimes it can be as simple as taking engaging photographs. Sometimes you just need to move on and come up with a new design. Maybe even take the time to learn a new technique to put you ahead of the curve.

Good products take time to develop, the first thing you decide to make/sell probably won’t be a showstopper. But you get feedback from people, revise, see what the market’s into, and try again. Focusing on your marketing before you develop a good product is like putting fancy wheels on a car with a dud engine. You gotta get the basics down before you can polish.

The other bonus to continually working on your products is that new products bring repeat customers. And repeat customers tell their friends. And everyone lives happily ever after.

How much time per week do you spend on your business?

Most of it, but I try not to let it interfere with my personal life too much. The week before a craft show I probably work 10-12 hours a day, but most of the time I’m Tinysauring it up for a normal 8 hours. Taking a break, relaxing, and playing video games is important to keep up the will to wake up in the morning and do it all over again. At a day job you usually have a hostile boss, and you’re motivated by wanting to avoid his/her wrath. But self-employed it’s just you. You’ve got to motivate yourself.

Do you have any other sources of income besides your business?

Yes, I have a part-time work-at-home job which I was really lucky to score. It’s flexible enough that it’s not a huge strain on my Tinysaur time, and gives me the peace of mind to have my rent covered no matter what happens to my business. It’s not a huge chunk of money, literally just enough to cover rent, but it’s nice to have one income stream that’s consistent. Even if Tinysaur gets huge I’ll probably keep it, it’s a nice job.

Is there anything you’ve had to sacrifice to start your business?

There are things I’ve given up, and changes in my lifestyle, but I wouldn’t go so far as calling them sacrifices. I don’t buy new clothes on a monthly basis anymore, and I go to the bar a lot less (which is probably a good thing), but those have been pretty easy to adjust to. And in return I get to spend more time with my friends and boyfriend, do my shopping during the week when the stores are quieter, sleep in when I’ve been out too late, and generally lead a much less stressful life. I still stress out sometimes, because I am a worrier, and there are definitely many times when I’m not sure I can actually do this. But between those moments of self-doubt I’m really happy.

What are your plans for the near future?

Plans? I’m supposed to have plans? Uh..

Seriously though, I do have some tricks up my sleeve. A friend of mine is going to work with me to get Tinysaur in some local stores, so I’m working on getting all my wholesale stuff ready and organized (line sheets, catalogs, etc). So far I have my stuff in a couple places but I’m looking for world domination!

I’m doing a few craft shows this season, but not really making that my main focus. I’ve still kind of sworn them off, I’m just not outgoing enough to really get into enjoying them. And I have some exciting press features coming up, which will hopefully lead to more wholesale, more press, etc.

Lastly I’m getting ready to launch my own website with it’s own shopping cart so I can have more hands-on control of my brand. It’s a lot of work, but I’m pretty stoked about it all.