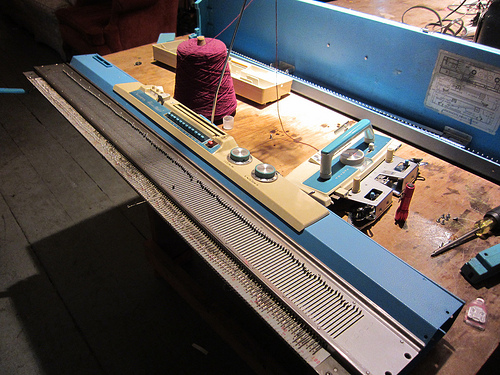

A few years ago I was given a Toyota K747 knitting machine, a gorgeous blue knitting machine that features a punchcard patterning system. It is by all counts a fascinating machine, and I was excited to receive a lace carriage for it today.

It’s been a while since I’ve devoted time to the knitting machine – they’re a bear to set up and take down so without somewhere to leave it set up all the time it can be daunting to use.

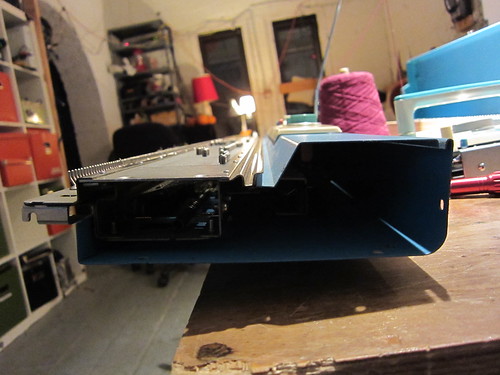

I noticed that one of the screws on the side wasn’t biting into anything, and decided to take the machine apart to figure out what was missing. I took out 6 screws on each end, and pulled off the end caps.

With the caps off I could stare into the dark abyss of needles and gears. I discovered it’s really challenging to take photos down a long, dark tube when using a point and shoot camera, so forgive the image quality of the following photos.

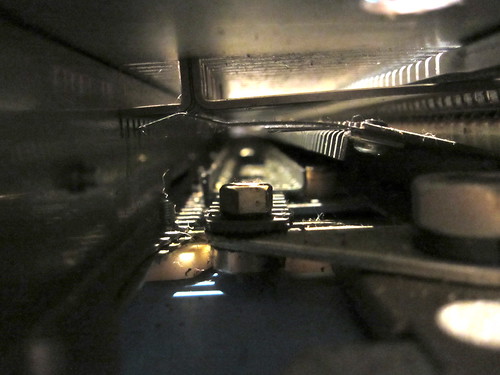

There are two “compartments” inside the machine, the front area which is all metal and has slots at the top for the needle tabs (called the needle butt) to stick out of, and the back which is mostly plastic where the needle butts rest. This is also where the patterning shafts (for lack of a better term) are located.

Here’s the front compartment, the front of the machine is to the left. If you have trouble seeing the needle tabs, click the image for an annotated version.

Here’s the back. You can see there’s some greasy dusty areas. I’m not sure how to get in there to clean it. The needle shanks are pointing down to the “shafts”, which if you look closely you can see there are 12. The Toyota K747’s repeat is 12 stitches wide.

The missing part in question is a small rectangular nut which slides into the end cap. I’m really hoping this is something I can source rather than having to mill/tap one myself. Any suggestions for shortcuts are appreciated.

Aside from the missing nut, the machine is in great shape, and the nut isn’t super crucial to the machine’s operation. My next step is to find a scale version of one of the punch cards so I can cut some out on the laser cutter. I found a few places that claim to sell punch cards for it but none of them had them in stock.

Hola soy de Mexico, estoy a punto de comprar una toyota 747, con todas sus piezas, y en buen estado, cual crees que seria un precio justo?

saludos

Hi Hector,

I’m not really sure what a good price is for a 747 since mine was free + broken. I would say that most of the japanese machines go for $200 – $300 US dollars, more if all the parts are there and generally much more if there is a ribber as well. Check Ebay for similar machines to get an idea of the current rate.

Were you ever able to laser cut a punch card for this knitting machine? I am in the process of figuring out how to laser cut my own cards and have not been able to determine what material to use. I did find an extremely helpful website for creating the designs however – http://oknitme.serpicanaro.org/.

If you have any material advice I would be very appreciative!

I think 80 pound cardstock should be just fine. If that isn’t durable enough, mylar is both flexible and laserable.

I have been searching for help for my Toyota KS787, I cannot get it to make a patter at all. No matter the card or the lever settings, I get only 2 needles per repeat which will pop out. Has anyone seen the service manual for this available? I’d really like to have patterns and not just stockinette. I’m concerned about taking much more apart than I have already with no guide.

Thanks

Boa tarde!

Eu sou do Brasil. Necessito saber onde posso encontrar peças de reposição para Toyota K747, pois no meu país não existe, ela foi muito pouco comercializada no Brasil.

Agradeço sua atenção.

The only replacement parts available at this point are used ones, so your best bet is to try eBay (if you’re not finding much on your country’s eBay you can try another’s, I get most of my Superba parts from eBay France.

Interesting to read!

I have a fellow member in a Swedish machine knitting group that also has this machine. For her I’m asking:

Where do you purchase the 12 stitches punch cards or do you make them yourself?

I have seen selfmaking of the 24 stitches card out of paper with a plastic film on.

Best regards