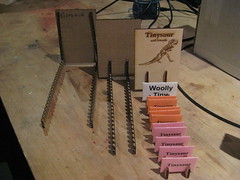

My packaging has been through a number of iterations since the first Tinysaur was shipped.

The first was an “Oh no I need packaging” sort of thing, where I haphazardly went to Duane Reade to pick up the least boring paper I could find – which turned out to be construction paper.

I ran the construction paper through a laser printer (as in toner, not coherent light) to throw the word “Tinysaur” on the outside, and then cut the envelope shape out on the laser cutter. I didn’t really have a decent method for registration (lining up the print with the cutting) so it took a while. And folding the little envelopes turned out to be a pain.

I didn’t really have a decent method for registration (lining up the print with the cutting) so it took a while. And folding the little envelopes turned out to be a pain.

After having to recruit friends to help me fold tiny envelopes during the holiday rush, and running out of construction paper, I got a little smarter. I started using bags with staple-tags, much easier to cut. Now they look almost respectable.

But they were still not quite ready for a retail-side display… which I realized when I was talking to a purchaser for a chain of museum shops. Oops.

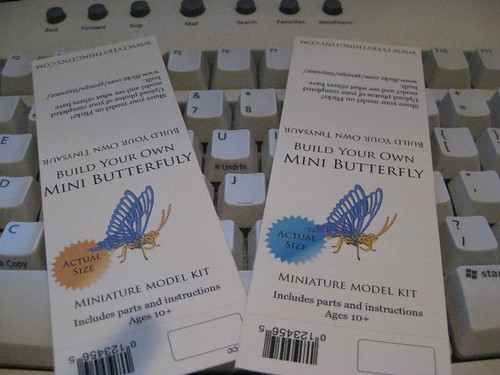

Which brings me to my current matchbook-style packaging. It takes a little more energy than the staple-tag, but feels nice and solid, and gives me plenty of room for marketing copy (uh… about that…).

Which brings me to my current matchbook-style packaging. It takes a little more energy than the staple-tag, but feels nice and solid, and gives me plenty of room for marketing copy (uh… about that…).

Next on my packaging to-dos is to redesign the instruction sheets, which I’ve been putting off for a while. Ugh.